Quality Control At Hielite

Inspecting for Perfection

BSCI, GRS, GOTS, RMS, RWS, FEM, and SLCP verified.

5 Inspection Process For Defect Elimination

We implement quality management in the whole process of hat production: from fabric to semi-finished products, finished product packaging, etc., to ensure the quality of the final products. At present, there are 20+ quality inspectors and 10+ inspection machines.

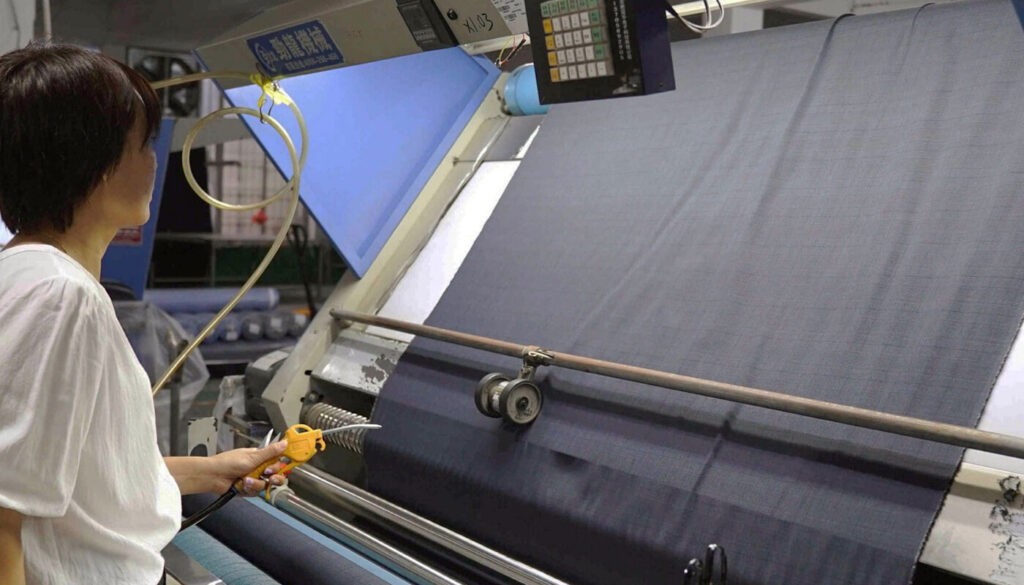

Fabric Inspection

During the first step, our engineers will check the quality of materials such as fabrics, threads, and embellishments to ensure they meet the standards for the custom hats.

Inspection items:

Appearance, weight, density, feel, pattern, color, width, length, weft skew, and weft arc of the fabric.

We use a four-point inspection method, and each yard of defects will be rated as four points for severe deficiencies.

Example: All holes will be rated four points regardless of their diameter.

Certifications

Hello! What do you need help with?